As non-destructive testing (NDT) technologies continue to develop, new and more interesting ways of using them are also emerging. It’s no wonder, then, that there is so much confusion surrounding these technologies and their capabilities. Here are four tips that you may not know about NDT technologies.

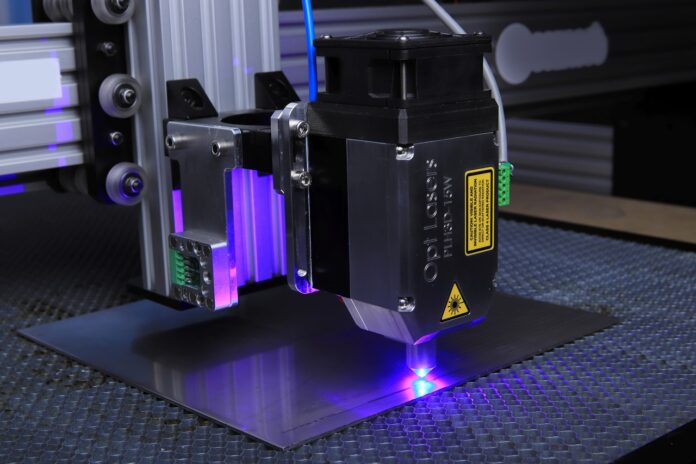

1. Laser shearography can be used to inspect composite materials.

Laser shearography is a form of NDT that uses laser light to create an interference pattern on the surface of a material. This interference pattern can then be analyzed to detect defects in the material. Composite materials are particularly well suited for this type of testing, as they often have complex geometries that make them difficult to inspect using other methods. Also, laser shearography can be used to inspect very large areas quickly and efficiently. It’s a great choice for inspecting composite materials for both quality control and research purposes. This technology is also becoming increasingly popular for inspecting 3D-printed parts.

2. Thermal imaging can be used to detect leaks

Thermal imaging is another form of NDT that uses infrared (IR) radiation to create an image of an object. This image can then be analyzed to detect anomalies, such as leaks. Thermal imaging is particularly well suited for detecting leaks in pipes and other types of tubing. It’s also useful for detecting leaks in roofs and other types of building envelope systems. Additionally, thermal imaging can be used to detect electrical problems, such as loose connections and overloaded circuits. If you’re looking for a way to find hidden problems, thermal imaging is definitely worth considering.

3. Eddy current testing can be used to inspect non-conductive materials

Eddy current testing is a form of NDT that uses magnetic fields to inspect conductive materials. However, it can also be used to inspect non-conductive materials, such as composites and plastics. This type of testing is particularly well suited for inspecting materials for surface defects, such as cracks. Additionally, eddy current testing can be used to detect subsurface defects, such as denominations. This type of testing is often used in the aerospace and automotive industries. If you need to inspect non-conductive materials for defects, eddy current testing is definitely worth considering. It’s also a good choice for inspecting materials for corrosion.

4. Ultrasonic testing can be used to inspect a wide variety of materials

Ultrasonic testing is a form of NDT that uses high-frequency sound waves to inspect materials. This type of testing is very versatile and can be used to inspect a wide variety of materials, including metals, plastics, ceramics, and composites. Ultrasonic testing is particularly well suited for detecting defects that are not visible to the naked eye. It’s also useful for detecting defects that are internal, such as cracks and voids. Additionally, ultrasonic testing can be used to measure the thickness of materials. This type of testing is often used in the aerospace, automotive, and oil and gas industries. If you need to inspect materials for defects, ultrasonic testing is definitely worth considering. It’s also a good choice for measuring the thickness of materials.

There are many types of NDT technologies, and each has its own unique capabilities. These four tips should help you to better understand the capabilities of these technologies and how they can be used to improve the quality of your products. Also, keep in mind that new technologies are constantly being developed, so the capabilities of NDT technologies are constantly evolving. If you have a specific application in mind, it’s always a good idea to consult with an NDT expert.