It is expected that the 3D printed medical device market will double from 2018 to 2022 at a CAGR of 17,5 percent. CAGR is the abbreviation of compound annual growth rate, by the way. 3D printing San Diego will thus be used more and more in the medical sector in the coming years. In fact, this rise has already started and will continue for a few more years. This leap is the case due to several factors. These include technological developments, but also possibilities for mass customization, increased funding, and growing devices in the healthcare sector. These applications can be used by physicians, but for patients, 3D printed products will be developed as well. Below you can find more about that.

3D printed products for physicians

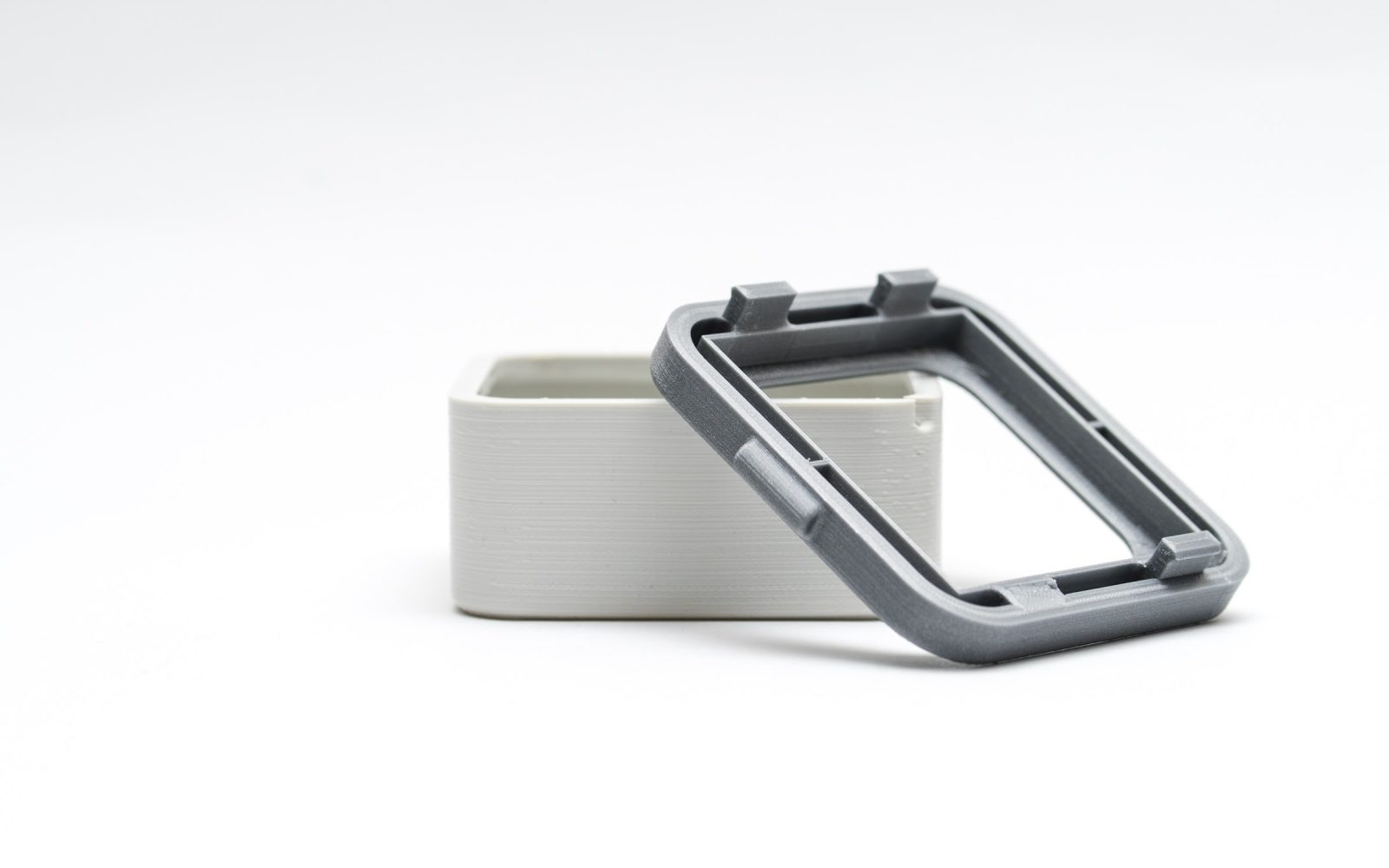

3D printed tools that are used by physicians can be surgical tools and guides. These devices can be used by doctors, surgeons, and dentists. They can be 3D printed with individual specifications if this is needed. Especially the surgical guides will likely account for the biggest share of growth in the coming years. By using 3D scanning surgeons can improve their planning, which is done by printing patient-specific anatomical models in order to practice. These can also be used to develop better implant fits or just to simply give more visual information. This will result into a reduction in the surgery time, while it also reduces the possibility of infection. Furthermore, 3D printing not only offers instruments printed on demand, but it can also improve the function of surgical tools. This is done by optimizing the design, which can be done with sheet metal fabrication too.

Products for patients

Medical devices that have been made by using 3D printing can also be used by patients. Examples of these tools are prosthetics and implants for example. These mostly benefit since 3D printing enables the devices to be customized. Parts can be created in order to fit the exact anatomical specifications of all patients. Besides that, they can be 3D printed quickly and affordably. Traditional manufacturing would need several casting processes and cost much more because of that than 3D printing. This process can thus be used to create affordable and lightweight prosthetics, which is already done by several major companies. The cost efficiency is not the only reason why 3D printing is used to create products for patients, this is also the case due to the customization abilities.

Clothes

Fast fashion is seen as a big problem nowadays. 3D printing may solve this issue. In fact, it is seen as the future of fashion by many designers. 3D printing is not new in this industry, instead, clothes have been made with the help of this process for quite some time now. You could even create your own clothes if you own a 3D printer or hire a 3D print service.

Organs

3D printers can be used to manufacture products, but these machines are also capable of bioprinting actual functioning organs. On the internet, there are even stl files available for a human kidney, liver, and heart. This sounds crazy but is actually very good news for the medical sector since there is a shortage of donor organs at the moment.